Energy and Process Engineering (EVT)

Efficient utilisation of low-temperature heat

We encounter thermal energy at a temperature level of up to 150°C in many different areas. Large amounts of energy in this temperature window are available to us from renewable energies, especially geothermal energy. However, waste heat is also generated in the form of waste heat from numerous industrial processes, which could be fed back into the process or used elsewhere. The Energy and Process Engineering EVT department at ITES is concerned with methods for the efficient utilisation of low-temperature heat. The focus of the department is on experimental work, although simulation calculations are always carried out in parallel. Various internships, Bachelor's or Master's theses can be carried out within the projects. Interested parties can contact the above-mentioned employees at any time to jointly define a suitable task.

Thermo- and fluid dynamics

Power Plant Technology

- Investigation of thermodynamics and fluid dynamics in supercritical media

- Thermodynamic simulation calculations of power plant processes

- Adaptation and optimisation of organic Rankine cycle processes to site-specific conditions

- Sector coupling

Heat transfer

- Design and adaptation of heat exchangers

- Heat transfer analyses

- System simulation of heating networks and systems

- Optimisation of coolers and condensers

- Heat management of technical systems / utilisation of industrial waste heat using the example of an injection moulding machine

- Separation and binding of CO2 from the atmosphere

Heat pumps

- Simulation of the thermodynamic cycle of heat pumps

- Investigations into heat storage with phase change

Geothermal energy

Geochemistry

- Prevention of precipitation using inhibitors or CO2

- Investigation of the interaction of thermal water and rock

- Bypass tests for scale formation

- Exposure of material samples in a corrosion loop

Water treatment

- Electricity-autarkic water treatment using waste heat (OSCAR)

Thermal water cycle

- Determination of physical material properties of thermal waters

- Extension / validation of material data for geothermal cycle processes

Ongoing projects

- MoNiKa: Transient simulation of operating modes

- OSCAR: Commissioning of a water treatment plant

- SCHUTZGRUND: Investigations for the protection of the deep subsurface from modified geothermal fluids

- Accompanying research project "Digital Twin" for the DAAD Double Degree Master with ITBA Buenos Aires

- Energy flows in an injection moulding machine (together with IAI and IAM)

Completed projects

- EvA-M2: Evaluation of precipitation inhibitors for the Molasse Basin

- EIKE

- RIAS

- PETher/MobiFlow

Methods:

- Laser-optical flow, temperature and species measurements in reaction chambers

- Porosity and surface determination of solids

- Particle size determination and particle distribution

- Concentration measurement of solids in liquids using absorption measurement

- Two-phase measurement technology

Contact:

Dietmar Kuhn∂kit edu

Hydrothermal Reaction Apparatus

more

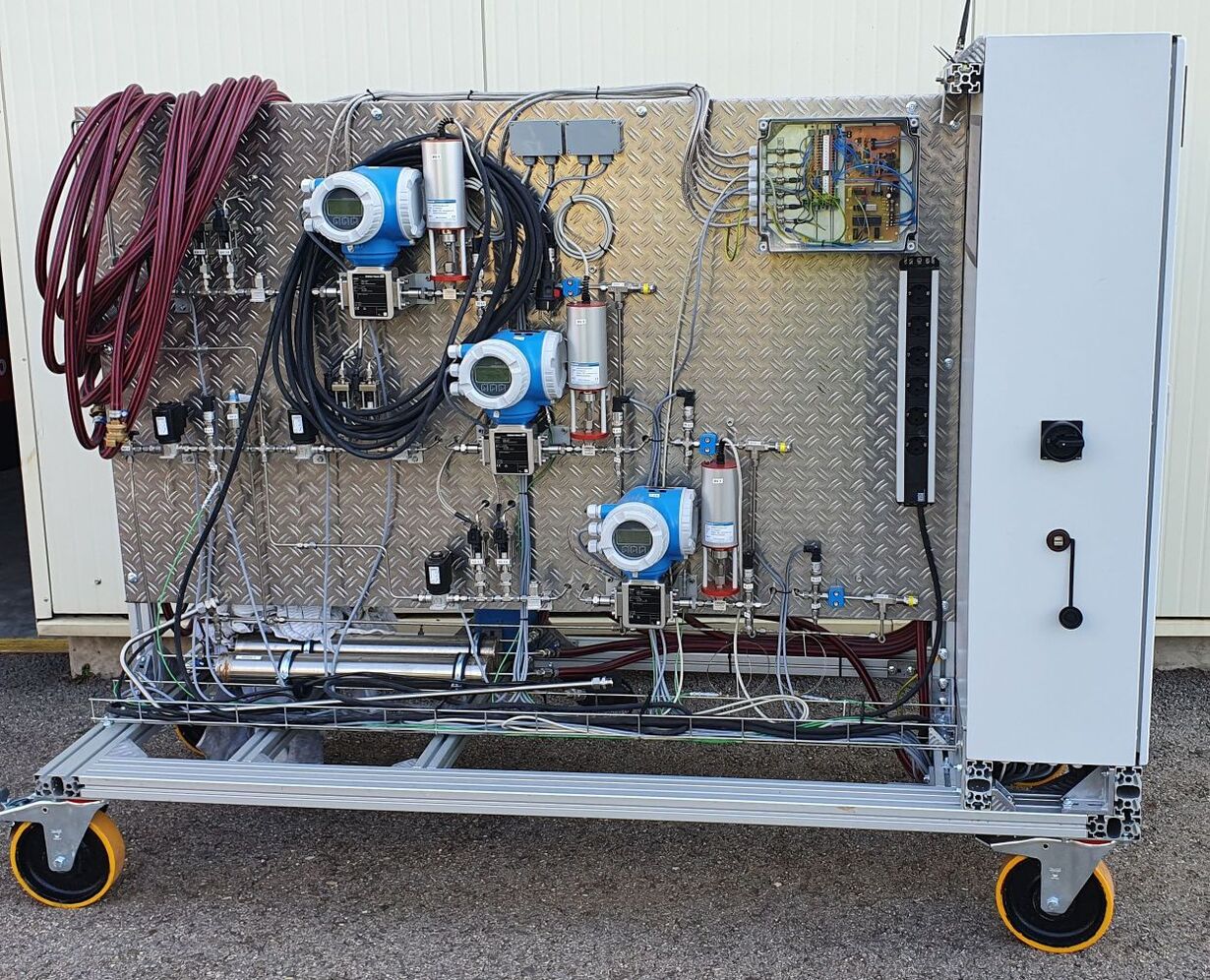

Open Steam Cycle for Autarc water Reuse and purification

MORE

Filterbypass und Gasabscheidung

more